Slot Power

(Previously known as Power Slot or SportStop)

Power Slot Cryo. Frozen Rotors has teamed up with Power Slot to develop Power Slot-Cryo, cryogenically treated brake rotors. Power Slot rotors are designed to beat the challenges of high performance driving and severe duty brake demands, and represent one of the most cost-efficient performance brake upgrades offered in the market today. Track Power is a simple to use slot car track designer. It is no longer in development as the website TrackPower.net is no longer in use. Features include track libraries, individual lane selector tool to calculate lane distance, measurement tool and more. You can print the schematic, color coded track view, or detailed track.

StopTech Sport - The Performance Brake Professionals

StopTech Sport (Previously known as Power Slot or SportStop) - The Performance Brake Professionals black lettering Whether you drive a sports car, SUV, truck or sport compact, StopTech Sport has a brake rotor for your vehicle. With over 1200 vehicle fitments, StopTech Sport is the undisputed leader in high-performance replacement rotors. All of StopTech Sport's rotors are designed to run cooler and promote improved wet and dry brake performance and slotted rotors retain more surface area than drilled rotors, meaning more stopping friction. StopTech Sport pioneered the performance rotor business years ago and since then they've never lost their focus. Tapered slot technology creates a vent for brake dust and pad gasses while preserving strength. Brightly plated to enhance the look of custom wheels. StopTech Sport rotors are also available cryogenically treated. Although not apparent to the naked eye, rotors treated cryogenically show significant improvements in abrasive wear resistance and durability while also reducing residual stresses for an extra level of protection against warping.

At StopTech Sport, they live by one simple motto: Premium Quality Equals Premium Performance. They believe that all of their products must exceed the fit, finish and performance of the Original Equipment rotor on your car. That's why they're known as the Performance Brake Professionals!

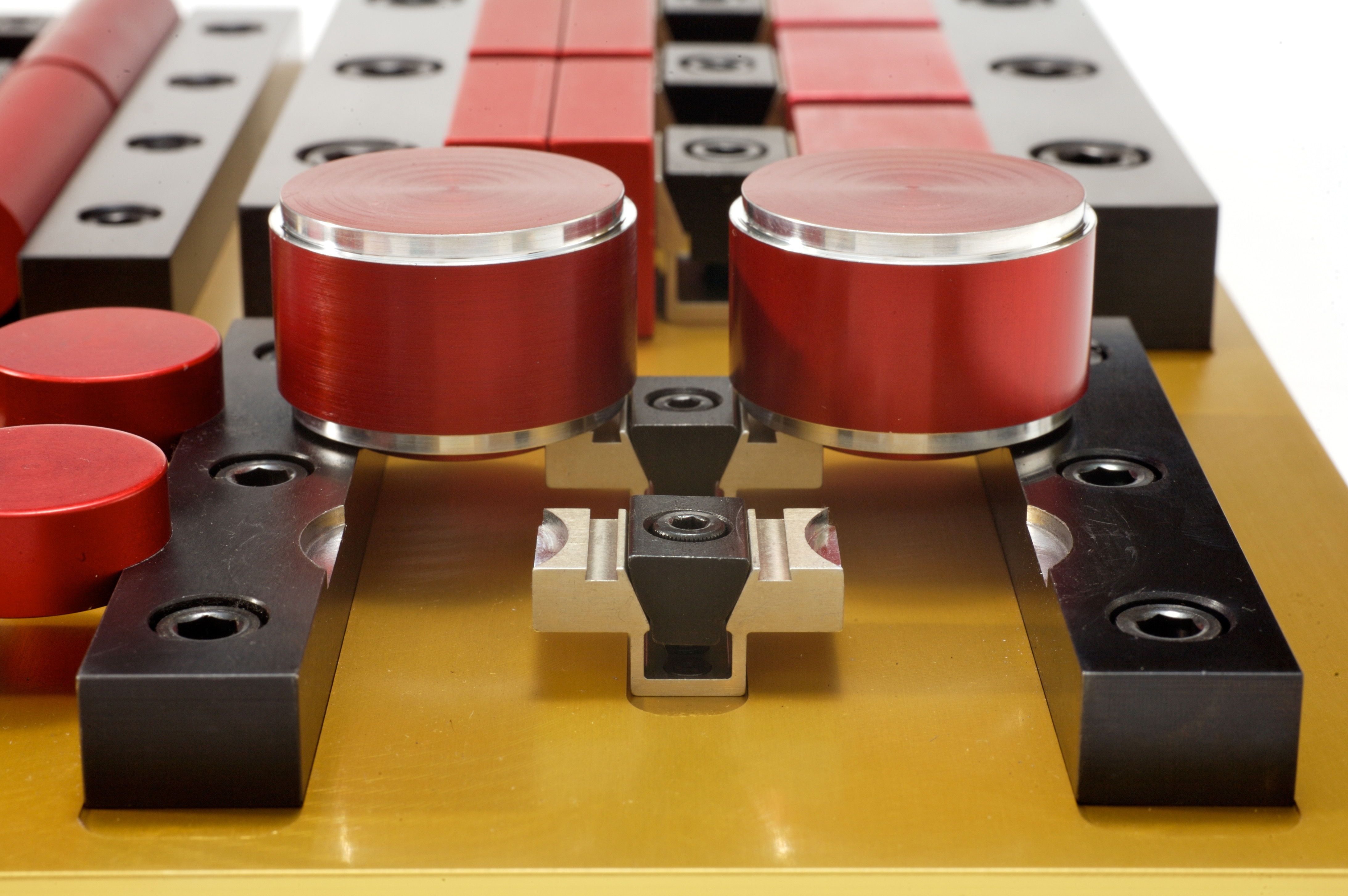

Stoptech Sport Slotted, Drilled, And Drilled, Slotted And Cryo (cryogenically treated) Brake Rotors.

Any of these rotors can be ordered as a Stoptech Sport Cryo Brake Rotor.

Stoptech Sport Slotted

- Prevents glazing of the pads, adds bite and improves wet and dry braking performance.

- Produced from a high quality Centric Parts® blank casting and finished in a durable e-coating for corrosion resistance.

- Look great behind custom wheels, improve the initial bite of the brake pads, and help wipe away the debris that forms between the pad and the disc.

- Most are finished with black e-coating on both sides of the hat, inside the cooling vanes, and on the outside edge.

- E-coating is a superior electro-statically applied finish designed to withstand 400 hours of salt water exposure without rusting.

- Power Alloy metallurgy is an exclusive feature of many StopTech® rotors.

- In specific vehicle applications, StopTech works with foundry partners to increase the molybdenum or carbon content of the castings, and to carefully control the cooling rate during production to reach targets for hardness and tensile strength.

- Nearly all StopTech® 1-piece rotors have unique slot or hole patterns for the left and right sides of the vehicle. For these directional patterns, straight vane or pillar vane rotors are used to ensure that a drilled hole never touches a cooling vane.

- Look for Series 126 rotors.

Stoptech Sport Drilled

- Prevents glazing of the pads, adds bite and improves wet and dry braking performance.

- Produced from a high quality Centric Parts® blank casting and finished in a durable e-coating for corrosion resistance.

- Look great behind custom wheels, improve the initial bite of the brake pads, and help wipe away the debris that forms between the pad and the disc.

- Most are finished with black e-coating on both sides of the hat, inside the cooling vanes, and on the outside edge.

- E-coating is a superior electro-statically applied finish designed to withstand 400 hours of salt water exposure without rusting.

- Power Alloy metallurgy is an exclusive feature of many StopTech® rotors.

- In specific vehicle applications, StopTech works with foundry partners to increase the molybdenum or carbon content of the castings, and to carefully control the cooling rate during production to reach targets for hardness and tensile strength.

- Nearly all StopTech® 1-piece rotors have unique slot or hole patterns for the left and right sides of the vehicle. For these directional patterns, straight vane or pillar vane rotors are used to ensure that a drilled hole never touches a cooling vane.

- Look for Series 128 rotors.

Slot Powers Casino

Slot Powerbank Veger

Stoptech Sport Drilled and Slotted

How Much Is Slot Power Bank

- Prevents glazing of the pads, adds bite and improves wet and dry braking performance.

- Produced from a high quality Centric Parts® blank casting and finished in a durable e-coating for corrosion resistance.

- Look great behind custom wheels, improve the initial bite of the brake pads, and help wipe away the debris that forms between the pad and the disc.

- Most are finished with black e-coating on both sides of the hat, inside the cooling vanes, and on the outside edge.

- E-coating is a superior electro-statically applied finish designed to withstand 400 hours of salt water exposure without rusting.

- Power Alloy metallurgy is an exclusive feature of many StopTech® rotors.

- In specific vehicle applications, StopTech works with foundry partners to increase the molybdenum or carbon content of the castings, and to carefully control the cooling rate during production to reach targets for hardness and tensile strength.

- Nearly all StopTech® 1-piece rotors have unique slot or hole patterns for the left and right sides of the vehicle. For these directional patterns, straight vane or pillar vane rotors are used to ensure that a drilled hole never touches a cooling vane.

- Look for Series 127 rotors.